Texture profile analysis and sensory evaluation of commercially available gluten-free bread samples

- Original Paper

- Open access

- Published: 19 March 2022

- Volume 248 , pages 1447–1455, ( 2022 )

Cite this article

You have full access to this open access article

- Marcell Tóth ORCID: orcid.org/0000-0002-3214-3802 1 ,

- Tímea Kaszab 1 &

- Anikó Meretei 1

9142 Accesses

15 Citations

Explore all metrics

The need for better quality gluten-free (GF) bread is constantly growing. This can be ascribed to the rising incidence of celiac disease or other gluten-associated allergies and the widespread incorrect public belief, that GF diet is healthier. Although there is a remarkable scientific interest shown to this topic, among the numerous studies only a few deals with commercially available products. The gap between research and commercial reality is already identified and communicated from a nutritional point of view, but up to date texture studies of commercial GF breads are underrepresented. In this study, 9 commercially available GF bread were compared to their wheat-based counterparts from texture and sensory viewpoints. Results showed that among GF loaves products, some performed significantly better at hardness and springiness attributes during the 4-day-long storage test compared to the wheat-based products. Two of GF cob breads performed significantly better or on the same level as the wheat-based cob regarding to hardness and cohesiveness during 3 days. Among sensorial properties mouth-feel, softness and smell were evaluated as significantly better or similarly for some GF versus wheat-based products. Two GF bread had more salty taste which reduced the flavor experience. Both the texture and sensory data of the storage test indicate that the quality of some GF bread products has significantly improved in the recent years; they stayed comparable with their wheat-based counterparts even for a 4-day-long storage period.

Similar content being viewed by others

Semi‐volume gluten‐free bread: effect of guar gum, sodium caseinate and transglutaminase enzyme on the quality parameters

Technological Aspects of Gluten Free Bread

Gluten-Free Breadmaking: Facts, Issues, and Future

Avoid common mistakes on your manuscript.

Introduction

However, Celiac disease (CD) was already mentioned by Aretaeus of Cappadocia probably in the second century (AD) [ 1 ], it became an emphasized scientific and commercially important topic in the last decades. The consumption of gluten-free (GF) products is significantly increasing, just as the demand for good-quality GF products [ 2 ]. The underlying reason for the expanded interest can be attributed to better diagnostical methods of CD, wheat allergy, non-celiac gluten sensitivity and dermatitis herpetiformis [ 3 , 4 ], and to the widespread incorrect public belief that GFD is healthier [ 5 ].

Gluten—as a term used to encompass prolamin proteins—can be found in wheat, barley and rye, including all their subtypes and genus [ 6 ]. It is the key structure-forming protein, which is the most common and important protein ingredient in the bakery industry. Absence of gluten in the GF formulation ends up with much weaker gas-holding properties; therefore, it causes low loaf volume [ 7 ], crumbling texture, poor color [ 8 ], choky dry mouth-feel and shorter shelf life [ 9 , 10 , 11 ].

Consumer survey studies revealed that the consumers are satisfied with the quality of GF sweets, biscuits and pasta, but still significant improvement is needed in GF bread and cakes to meet the consumers’ expectations [ 12 , 13 , 14 ]. The constantly growing number of published articles shows that several approaches were studied mostly using different modified starches, pseudocereals, enzymes, protein supplementation and/or hydrocolloids to improve the quality and nutritional properties of GF flours and breads [ 6 , 15 ]. Among these numerous studies, only a few deals with commercially available products, the majority rather focuses on self-made prototypes from different raw materials. The publications that are based on commercial products concentrate on composition, nutrition values and/or prices. Based on their detailed and thorough study by examining 228 commercial products Roman et al. [ 12 ] declared a gap between commercial reality and research. Studying the ingredient list of breads they noticed that the commercial breads do not seek to use one single starch or gluten replacer, but a combination of several ingredients to optimize bread quality (hydrocolloids, acidifiers, emulsifiers, leavening agents, preservatives, and aromas or flavorings). They observed that some ingredients which have momentous attention and focus in the scientific world (e.g., pseudocereals) are hardly used in commercial products. On the UK market, GF products are 159% more expensive than their regular version, most GF bread and flour products contain higher amount of salt, fat and sugar, while some GF products are lower in fiber and protein content [ 16 ]. Similar differences were found on the Italian market [ 17 , 18 ]. Spanish market sample study revealed that sodium, fat and cholesterol content were significantly higher in 20 commercial GF bread samples due to having egg, different oils like coconut, olive, sunflower, palm [ 19 ]. Although it is true that dietary fiber and sugar levels are more adequate than in the past, the GF diet might lead to CD patients’ inadequate intake of fats, proteins, sodium and vitamins [ 20 ].

In general, it can be declared that GF products are significantly more expensive compared to their wheat-based counterparts, and their on-shelf availability can be limited [ 21 , 22 , 23 ].

The studies mentioned above, give important and valuable information for the scientific community and draw attention to the gap between research and commercial reality. Despite the fact that this gap is already identified and communicated from a nutritional point of view and regarding ingredients, up to date rheological studies are hardly available dealing with commercial GF breads (Table 1 ).

Considering the rapid and constant development and changes in the GF bakery industry (ingredients, technologies, consumer needs), more and more GF bakeries are appearing on the market and selling freshly baked, preservative-free bread products. These products are based on different ingredients and recipes, but trying to be comparable with the gluten containing products in terms of lookalike, size, taste and shelf life. Therefore, it would be essential to continuously examine the textural and sensory properties of the GF freshly baked and sold bread products available on the different local markets. Following this approach, the current study aims to compare these GF commercially available, preservative-free bread products with their gluten containing wheat flour-based counterparts, focusing on their texture and sensory properties.

Materials and methods

Bread samples.

The studied 9 different GF commercial bread samples were purchased from different specialized GF bakeries, while the wheat-based products from a supermarket. All the samples were selected with the aim to compare them regarding the product’s name, appearance and packaging. Special attention was taken to ensure that the products did not contain preservatives and gas or modified atmosphere in the packaging. In this study, three types of bread were selected: cob (artisan, round shaped bread), white and wholegrain loaf (baked in loaf tin). From each bread type, GF and wheat-based products were selected and compared (Table 2 ).

All the samples considered in this study were sliced and ready to eat, without prior heating requirement. Ingredients and nutrition values of the samples which were noted on the product’s packaging are presented in Table 3 .

Texture measurement

Texture profile analysis (TPA) was performed at room temperature using Stable Micro Systems TA.XT2. Samples were taken and measured from the first, middle and last third of the sliced bread products, doing 7 different measurements on different slices of the same bread sample. The measurement was placed on the middle of the bread slices, avoiding region near to the crust. Each bread slice had 12 mm thickness. The applied settings were 35 mm diametric acryl cylindrical probe, 50% strain, 5 mm/sec crosshead speed and 5 s of waiting time between the two measurements. Firmness, cohesiveness and springiness were the main representative parameters of the sample texture. Results obtained from the GF and wheat bread samples were compared and followed up.

Sensory evaluation

During the sensory evaluation group of 15 people (13 females and 2 males, aged between 22 and 47 years) tested the bread samples. The ethical statement for the study was applied from the Hungarian University of Agriculture and Life Sciences and informed consent was obtained from each subject prior to their participation in the study. Subjects confirmed not having any known gluten, rye, milk protein, egg or lactose consumption-related disorder. All participants were recognized as regular bread consumers, consuming bread at least once per day.

The assessors received 1 full slice of the sample without any spreading, and were asked to appraise the intensity of 17 sensory attributes, which were described as relevant ones for GF bread by Pagliarini et al. [ 34 ] to cover appearance, color, taste and texture. For evaluation purpose a continuous, unstructured 10 cm long line scale with extremes at the ends (absolutely not intense and immensely intense) was used for every attribute. Samples were served with 3-digit codes on white plastic plates under white light at room temperature.

Data analysis

Received data were analyzed with IBM SPSS Statistics 25.0.2.2 software. Significant difference between the measured groups was determined by one-way analysis of variance (ANOVA) with 95% confidence level. Tukey HSD test was used after normality and standard deviation homogeneity test. Linear discriminant analysis (LDA) was performed to examine the separability of each bread type. Sensorial test data were analyzed by ANOVA. When there is significant difference, Tukey test was applied using a level of 5% of significance.

Results and discussion

Nutritional values of the bread samples.

In line with the previously published data, the examined GF bread samples contained different starches, hydrocolloids, fibers and protein supplements all at the same time. The type of starches (corn, tapioca, potato, and rice) and hydrocolloids (HPMC, guar gum, xanthan gum) were the most commonly used ones among various GF breads on different markets [ 12 , 17 ]. The fiber and salt content of C1, WL1 and WG1 samples were higher while the protein content was lower than in their wheat-based counterparts. Lower protein level was also detected for GF breads previously [ 12 ], but in this case of C1, WL1, WG1 samples according to the statement on the manufacturer’s website keeping the protein level low was a conscious decision, so their products can be used for people diagnosed with phenylketonuria (PKU) as well. People with PKU have to follow a low protein and phenylalanine containing diet [ 35 ]; therefore, these products are suitable not just for celiac people. Following gluten-free option as dietary practice is known and should be followed [ 36 ]. The energy and carbohydrate values were similar between the GF and wheat-based samples expect for WL2, which had the lowest level of energy and carbohydrate level among all the samples.

Texture profile changes

Results of the TPA measurements during the shelf-life test are presented in Table 4 . Overall, it can be seen that C2 sample had significantly ( p < 0.05) higher hardness but lower cohesiveness during the whole study. C1 was significantly softer on day 1, but not different from CW on the following days. C3 showed non-significant difference in hardness from CW during the whole study. Among the GF white loaf samples compared to WLW, WL1 was significantly lower in hardness except on day 3, while WL2 was also significantly softer versus WLW except for day 2. WL3 after day 1 was not significantly different from WLW. In case of whole grain loaves, on day 1 all the GF samples were significantly softer than WGW. On the following days, there were no significant difference detected among them, except for day 3, when WG1 was significantly softer versus WGW.

High cohesiveness leads to no disintegration during mastication, in case of low cohesiveness the bread crumbles [ 37 ]. Crumbling texture of GF bread during storage test was reported in the last decades, raising awareness as a general quality issue of these products [ 38 ]. Moore et al. [ 25 ] experienced decrease in cohesiveness ( p < 0.01) in GF bread samples after a two-day storage. In this study, all the GF white loaf samples had significantly higher cohesiveness during the storage test versus the wheat-based white loaf sample. In case of whole grain samples, WG1 was not significantly different in cohesiveness from WGW. WG2 and WG3 samples showed significantly higher values compared to WGW until day 4, when only WG2 was different. Among cob samples C2 and C3 were significantly different from CW, and in general C2 was different from the other cob samples during the whole study.

In bread, springiness is associated with freshness, and products with low values are linked with crumb brittleness [ 27 ]; therefore, having high springiness values during the shelf life is desired. In this study WL2 sample showed significantly ( p < 0.05) lower springiness during the 4-day-long storage test compared to all other bread samples. Despite the level of springiness grew day by day, but on the 4th day, it could barely reach 80%, still being more rigid. During the storage test, WL3 had significantly higher springiness values versus WLW sample, while WL1 was significantly better or comparable with WLW. Among the whole grain samples, WG2 showed higher springiness values every day compared to WGW, while WG1 and WG3 were better or comparable with WGW. Within the cob samples only on day 1 C1 showed significantly lower springiness value, but on the other days all the GF cob samples were comparable with the wheat-based cob.

Resilience characterizes the beginning of a sample’s elasticity and calculated from the ratio of the area under curve of the second half of the first cycle to the first half of the cycle. Reduction in springiness and resilience reflects alteration of the crumb elasticity [ 39 ]. The GF white loaves and the GF whole grain samples showed higher ( p < 0.05) resilience values compared to their wheat-based counterparts. This is in line with the springiness values, where the GF samples had higher or comparable values. In case of the cob samples, C3 always had higher ( p < 0.05) values than CW, C1 on days 1 and 4, while C2 was all the way consentaneous with CW.

According to the results, C1, C3, WL1, WL3, WG1, WG2 and WG3 bread samples in general can be described as soft and spongy [ 33 ] as they had comparable or lower hardness, higher springiness and resilience values than their wheat-based counterparts. From cohesiveness point of view the mentioned samples performed better or comparable to their wheat-based counterparts.

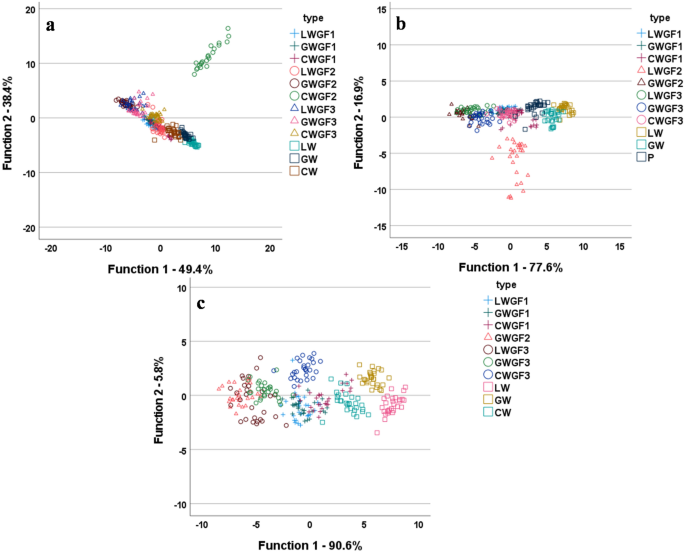

LDA results (Fig. 1 ) showed that WLW and WGW samples were classified as different groups from the others during the whole storage test. The significant difference in cohesiveness and resilience for both group, the springiness of WLW and the hardness of WGW attributes led together to show these samples as different product groups from the others.

LDA results of the storage test ( a with all samples; b without C2 sample; c without C2 and WL2 samples)

Due to its hardness results C2 was also classified as a separate group (Fig. 1 a), and WL2 because of its springiness and resilience attribute (Fig. 1 b). LDA result without these two groups (Fig. 1 c) showed an overlap between C1 and CW samples (79.3% of cross-validated grouped cases were correctly classified). This result clearly showed that the quality and texture profile attribute changes of C1 during a 4-day-long storage test were as good as the highest quality wheat-based product’s considered to be artisan.

Mean ratings (given in cm) for the 17 sensory descriptors of the 12 bread samples are presented in Table 5 . Less homogeneous crumb porosity for GF bread samples were previously reported [ 40 , 41 ], which was linked to high starch and low protein content, impacting the dough interfacial properties and rheological attributes. Pagliarini et al. [ 34 ] found commercial GF bread product with uniform crumb porosity but with higher protein value. The commercial GF samples included in the study had significantly lower protein content versus the wheat-based ones, but received as high or even significantly higher values for crumb homogeneity perception. The reason for that could be linked to more effective protein supplements and/or better understanding of starch–protein–hydrocolloid interactions.

From crumb color behavior point of view, participants found this attribute at same or more intense level than their wheat-based counterparts, except for WL3 and WG3. This result showed that it was achievable with the combination of GF ingredients like starches (corn, tapioca, rice), pseudocereals (amaranth, buckwheat) and fibers (apple, potato, psyllium) to create crumb color for GF breads, which was typical for the wheat-based counterparts, and preferable even for non-celiac consumers. However, the exact ratio just based on the ingredient list information could not be determined. The improvement of crumb and crust color intensity indicating that appearance, as one of the most important factors at bread purchasing had significantly improved in the last decade in the case of fresh baked GF breads.

One of the biggest struggle with GF bread formulations had been their flavor. GF products were often described as having dry, tasteless or unpleasantly strong corny taste [ 15 , 17 , 27 , 34 ]. In this study the GF samples did not have type-unusual corny and cheesy flavor and/or odor. From taste point of view, the two most dominant difference were detected by the saltiness of C1 and the sweetness of WGW. Latter can be explained with the highest level of added sugar (3.8 g/100 g).

WLW was characterized by the most intense fermented taste and smell, which was probably due to the presence of sourdough.

Concerning texture properties, sensory results were in line with the instrumental measurements. The link between hardness and springiness measurement and softness scores was confirmed, they strengthened each other. C2 sample was the hardest during all days, which was reflected in the sensory test as well with the least intense softness value. WL2 sample is not just hard, but also rubbery. However, the exact level of ingredients was not mentioned on the labels, which can be linked to a higher level of hydrocolloids.

In general, checking all the texture properties together, C1, WL1 and WG1 samples were performing at the same level or better ( p < 0.0.5) compared to their wheat-based counterparts.

This study aims to provide up to date data regarding the so far neglected topic of texture and sensory aspects of commercially available, freshly baked, preservative-free GF bread products designed for celiac consumers. Results show that the market has the ability to produce preservative-free, ready-to-eat bread products with comparable texture properties and attributes to their wheat-based counterparts during storage at room temperature. The higher fiber and the comparable or even lower energy and carbohydrates values decrease the gap in the nutrition area between GF and wheat-based bread products. In the future, it would be important that shelf-life studies aiming to evaluate the texture and sensory qualities of GF bread samples would concentrate on the commercially available GF products and in that case, these results and parameters could be used as reference. If the focus would shift more to the commercially available GF products, it would become more apparent that these products are not as low quality anymore. The hardness, springiness and cohesiveness data of the storage test prove the very opposite, the quality of these products has significantly improved during the last few years.

Availability of data and material

Data which support the outcome of the study are available from the corresponding author upon request.

Tekiner H (2015) Aretaeus of Cappadocia and his treatises on diseases. Turk Neurosurg 25:508–512

PubMed Google Scholar

Gobbetti M, Pontonio E, Filannino P, Rizzello CG, De Angelis M, Di Cagno R (2018) How to improve the gluten-free diet: the state of the art from a food science perspective. Food Res Int 110:22–32

Article Google Scholar

Ludvigsson JF, Leffler DA, Bai JC, Biagi F, Fasano A, Green PH, Hadjivassiliou M, Kaukinen K, Kelly CP, Leonard JN, Lundin KE, Murray JA, Sanders DS, Walker MM, Zingone F, Ciacci C (2013) The Oslo definitions for coeliac disease and related terms. Gut 62:43–52

Ortiz C, Valenzuela R, Lucero AY (2017) Celiac disease, non celiac gluten sensitivity and wheat allergy: comparison of 3 different diseases triggered by the same food. Rev Chil Pediatr 88:417–423

Hartmann C, Hieke S, Taper C, Siegrist M (2018) European consumer healthiness evaluation of ‘free-from’ labelled food products. Food Qual Pref 68:377–388

Capriles DV, Areas GJA (2014) Novel approaches in gluten-free breadmaking: Interface between Food Science, Nutrition, and Health. Compr Rev in Food Sci Food Saf 13:871–890

Article CAS Google Scholar

Elgeti D, Jeckle M, Becker T (2015) Strategies for the aeration of gluten-free bread—a review. Trends in Food Sci Technol 46:75–84

Conte P, Del Caro A, Balestra F, Piga A, Fadda C (2018) Bee pollen as a functional ingredient in gluten-free bread: A physical-chemical, technological and sensory approach. LWT Food Sci Technol 90:1–7

Ronda F, Perez-Quirce S, Villanueva M (2017). Rheological properties of gluten-free bread doughs: relationship with bread quality. Adv Food Rheol Appl 297–334

Martínez MM, Gómez M (2017) Rheological and microstructural evolution of the most common gluten-free flours and starches during bread fermentation and baking. J Food Eng 197:78–86

Rybicka I, Doba K, Binczak O (2019) Improving the sensory and nutritional value of gluten-free bread. Int J Food Sci Technol 54:2661–2667

Roman L, Belorio M, Gomez M (2019) Gluten-free breads: the gap between research and commercial reality. Compr Rev Food Sci Food Saf 18:690–702

Ozola L, Straumite E (2014) Characteristic of gluten-free products: Latvian consumer survey. Int J Nutr Food Eng 8:1848–1852

Google Scholar

Potter R, Stojceska V, Plunkett A (2014) An investigation of the consumer perception on the quality of the gluten and wheat free breads available on the UK market. J Food Meas 8:362–372

Capelli A, Oliva N, Cini E (2020) A systematic review of gluten-free dough and bread: dough rheology, bread characteristics, and improvement strategies. Appl Sci 10:6559

Fry L, Madden AM, Fallaize R (2018) An investigation into the nutritional composition and cost of gluten-free versus regular food products in the UK. J Human Nutr Diet 31:108–120

Foschia M, Horstmann S, Arendt EK, Zannini E (2016) Nutritional therapy - Facing the gap between coeliac disease and gluten-free food. Int J Food Microbiol 239:113–124

Cornicelli M, Saba M, Machello N, Silano M, Neuhold S (2018) Nutritional composition of gluten-free food versus regular food sold in the Italian market. Dig Liver Dis 50:1305–1308

Tres A, Tarnovska N, Varona E (2020) Determination and comparison of the lipid profile and sodium content of gluten-free and gluten-containing breads from the Spanish market. Plant Foods Hum Nutr 75:344–354

Melini V, Melini F (2019) Gluten-free diet: gaps and needs for a healthier diet. Nutrients 11:170

Missbach B, Schwingshackl L, Billmann A, Mystek A, Hickelsberger M, Bauer G, König J (2015) Gluten-free food database: the nutritional quality and cost of packaged gluten-free foods. PeerJ 3:e1337

Jamieson JA, Gougeon L (2017) Gluten-free foods in rural maritime provinces: limited availability, high price, and low iron content. Can J Diet Prac Res 78:192–196

MohdFauad SNA, Kaur S, Shafie SR (2020) Nutritional composition and cost differences between gluten-free and gluten-containing food products in Kuala Lumpur, Malaysia. Mal J Med Health Sci 16:178–183

Gallagher E, Gormley TR, Arendt EK (2003) Crust and crumb characteristics of gluten free breads. J Food Eng 56:153–161

Moore MM, Schober TJ, Dockery P, Arendt EK (2004) Textural comparisons of gluten-free and wheat-based doughs, batters, and breads. Cereal Chem 81:567–575

Hager AS, Wolter A, Czerny M, Bez J, Zannini E, Arendt EK (2012) Investigation of product quality, sensory profile and ultrastructure of breads made from a range of commercial gluten-free flours compared to their wheat counterparts. Eur Food Res Technol 235:333–344

Matos ME, Rosell CM (2012) Relationship between instrumental parameters and sensory characteristics in gluten-free breads. Eur Food Res Technol 235:107–117

Mariotti M, Pagani MA, Lucisano M (2013) The role of buckwheat and HPMC on the breadmaking properties of some commercial gluten-free bread mixtures. Food Hydrocoll 30:393–400

Wolter A, Hager AS, Zannini E, Arendt EK (2014) Influence of sourdough on in vitro starch digestibility and predicted glycemic indices of gluten-free breads. Food Funct 5:564–572

Mazzeo T, Brambillasca F, Pellegrini N, Valmarana R, Corti F, Colombo C, Agostoni C (2014) Evaluation of visual and taste preferences of some gluten-free commercial products in a group of celiac children. Int J Food Sci Nutr 65:112–116

Paciulli M, Rinaldi M, Cirlini M, Scazzina F, Chiavaro E (2016) Chestnut flour addition in commercial gluten-free bread: a shelf-life study. LWT Food Sci Technol 70:88–95

Feizollahi E, Mirmoghtadaie L, Mohammadifar MA, Jazaeri S, Hadaegh H, Nazari B, Lalegani S (2018) Sensory, digestion, and texture quality of commercial gluten-free bread: impact of broken rice flour type. J Texture Stud 49:395–403

Puerta P, Laguna L, Villegas B, Rizo A, Fiszman S, Tarrega A (2020) Oral processing and dynamics of texture perception in commercial gluten-free breads. Food Res Int 134:109233

Pagliarini E, Laureati M, Lavelli V (2010) Sensory evaluation of gluten-free breads assessed by a trained panel of celiac assessors. Eur Food Res Technol 231:37–46

Parlak O, Dundar AN (2021) Production of low protein and gluten-free cookies for phenylketonuria (PKU) and/or celiac patients. Czech J Food Sci 39:29–34

MacDonald A, van Wegberg AMJ, Ahring K, Beblo S, Bélanger-Quintana A, Burlina A, Campistol J et al (2020) PKU dietary handbook to accompany PKU guidelines. J Rare Dis 15:171

CAS Google Scholar

Onyango C, Mutungi C, Unbehend G, Lindhauer MG (2011) Modification of gluten-free sorghum batter and bread using maize, potato, cassava or rice starch. LWT Food Sci Technol 44:681–686

Naqash F, Gani A, Gani A, Masoodi FA (2017) Gluten-free baking: combating the chellenges—a review. Trends Food Sci Technol 66:98–107

Onyango C, Mutungi C, Unbehend G, Lindhauer MG (2010) Rheological and baking characteristics of batter and bread prepared from pregelatinized cassava starch and sorghum and modified suing microbial transglutaminase. J Food Eng 97:465–470

Pruska-Kedzior A, Kedzior Z, Goracy M, Pietrowska K, Przybylska A, Spychalska K (2008) Comparison of rheological, fermentative and baking properties of gluten-free dough formulations. Eur Food Res Technol 227:1523–1536

Witczak T, Juszczak L, Ziobro R, Korus J (2017) Rheology of gluten-free dough and physical characteristics of bread with potato protein. J Food Process Eng 40:1–21

Download references

Acknowledgements

The authors appreciated Barbara Pém and Nikolett Lázár for their high-level assistance in proofreading and editing. The authors acknowledge the Hungarian University of Agriculture and Life Sciences’ Doctoral School of Food Science for the support in this study.

Open access funding provided by Hungarian University of Agriculture and Life Sciences.

Author information

Authors and affiliations.

Institute of Food Science and Technology, Hungarian University of Agriculture and Life Sciences, Budapest, Hungary

Marcell Tóth, Tímea Kaszab & Anikó Meretei

You can also search for this author in PubMed Google Scholar

Corresponding author

Correspondence to Marcell Tóth .

Ethics declarations

Conflict of interest.

Authors have no conflict of interest to declare.

Compliance with ethics requirements

This article does not contain any studies with human or animal subjects.

Ethical approval

Ethics approval was not required for this study.

Additional information

Publisher's note.

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/ .

Reprints and permissions

About this article

Tóth, M., Kaszab, T. & Meretei, A. Texture profile analysis and sensory evaluation of commercially available gluten-free bread samples. Eur Food Res Technol 248 , 1447–1455 (2022). https://doi.org/10.1007/s00217-021-03944-2

Download citation

Received : 20 October 2021

Revised : 13 December 2021

Accepted : 18 December 2021

Published : 19 March 2022

Issue Date : June 2022

DOI : https://doi.org/10.1007/s00217-021-03944-2

Share this article

Anyone you share the following link with will be able to read this content:

Sorry, a shareable link is not currently available for this article.

Provided by the Springer Nature SharedIt content-sharing initiative

- Gluten-free bread

- Find a journal

- Publish with us

- Track your research

An official website of the United States government

The .gov means it’s official. Federal government websites often end in .gov or .mil. Before sharing sensitive information, make sure you’re on a federal government site.

The site is secure. The https:// ensures that you are connecting to the official website and that any information you provide is encrypted and transmitted securely.

- Publications

- Account settings

- My Bibliography

- Collections

- Citation manager

Save citation to file

Email citation, add to collections.

- Create a new collection

- Add to an existing collection

Add to My Bibliography

Your saved search, create a file for external citation management software, your rss feed.

- Search in PubMed

- Search in NLM Catalog

- Add to Search

Recent practical researches in the development of gluten-free breads

Affiliation.

- 1 Food Research Institute, National Agriculture and Food Research Organization, Tsukuba, Ibaraki 305-8642 Japan.

- PMID: 31304279

- PMCID: PMC6550274

- DOI: 10.1038/s41538-019-0040-1

Wheat bread is consumed globally and has played a critical role in the story of civilization since the development of agriculture. While the aroma and flavor of this staple food continue to delight and satisfy most people, some individuals have a specific allergy to wheat or a genetic disposition to celiac disease. To improve the quality of life of these patients from a dietary standpoint, food-processing researchers have been seeking to develop high-quality gluten-free bread. As the quality of wheat breads depends largely on the viscoelastic properties of gluten, various ingredients have been employed to simulate its effects, such as hydrocolloids, transglutaminase, and proteases. Recent attempts have included the use of redox regulation as well as particle-stabilized foam. In this short review, we introduce the ongoing advancements in the development of gluten-free bread, by our laboratory as well as others, focusing mainly on rice-based breads. The social and scientific contexts of these efforts are also mentioned.

Keywords: Nutrition; Technology.

PubMed Disclaimer

Conflict of interest statement

Competing interestsThe author declares that the author has no competing interests.

Comparison of the swelling mechanism…

Comparison of the swelling mechanism ( a ) and appearance ( b )…

Explanatory figure of particle emulsion/foam.…

Explanatory figure of particle emulsion/foam. Adapted from refs. , . Scale bar: 30…

Summary of the procedures for…

Summary of the procedures for making additive-free rice bread and “cooking tips” for…

Similar articles

- Quantitative Analyses of Key Odorants and Their Precursors Reveal Differences in the Aroma of Gluten-Free Rice Bread and Wheat Bread. Rohleder AR, Scherf KA, Schieberle P, Koehler P. Rohleder AR, et al. J Agric Food Chem. 2019 Oct 9;67(40):11179-11186. doi: 10.1021/acs.jafc.9b04800. Epub 2019 Sep 26. J Agric Food Chem. 2019. PMID: 31487164

- Nutritional therapy - Facing the gap between coeliac disease and gluten-free food. Foschia M, Horstmann S, Arendt EK, Zannini E. Foschia M, et al. Int J Food Microbiol. 2016 Dec 19;239:113-124. doi: 10.1016/j.ijfoodmicro.2016.06.014. Epub 2016 Jun 15. Int J Food Microbiol. 2016. PMID: 27321352 Review.

- Transamidation of gluten proteins during the bread-making process of wheat flour to produce breads with less immunoreactive gluten. Heredia-Sandoval NG, Islas-Rubio AR, Cabrera-Chávez F, Calderón de la Barca AM. Heredia-Sandoval NG, et al. Food Funct. 2014 Aug;5(8):1813-8. doi: 10.1039/c4fo00118d. Food Funct. 2014. PMID: 24917417

- Reduced-gliadin wheat bread: an alternative to the gluten-free diet for consumers suffering gluten-related pathologies. Gil-Humanes J, Pistón F, Altamirano-Fortoul R, Real A, Comino I, Sousa C, Rosell CM, Barro F. Gil-Humanes J, et al. PLoS One. 2014 Mar 12;9(3):e90898. doi: 10.1371/journal.pone.0090898. eCollection 2014. PLoS One. 2014. PMID: 24621595 Free PMC article.

- Hydrocolloids in gluten-free breads: a review. Anton AA, Artfield SD. Anton AA, et al. Int J Food Sci Nutr. 2008 Feb;59(1):11-23. doi: 10.1080/09637480701625630. Int J Food Sci Nutr. 2008. PMID: 18097842 Review.

- Effects of White Sorghum Flour Levels on Physicochemical and Sensory Characteristics of Gluten-Free Bread. Adzqia F, Suwonsichon S, Thongngam M. Adzqia F, et al. Foods. 2023 Nov 13;12(22):4113. doi: 10.3390/foods12224113. Foods. 2023. PMID: 38002171 Free PMC article.

- Rice-Based Gluten-Free Foods and Technologies: A Review. Park J, Kim HS. Park J, et al. Foods. 2023 Nov 13;12(22):4110. doi: 10.3390/foods12224110. Foods. 2023. PMID: 38002168 Free PMC article. Review.

- The Gliadin Hydrolysis Capacity of B. longum , L. acidophilus , and L. plantarum and Their Protective Effects on Caco-2 Cells against Gliadin-Induced Inflammatory Responses. Ramedani N, Seidita A, Asri N, Azimirad M, Yadegar A, Jahani-Sherafat S, Sharifan A, Mansueto P, Carroccio A, Rostami-Nejad M. Ramedani N, et al. Nutrients. 2023 Jun 16;15(12):2769. doi: 10.3390/nu15122769. Nutrients. 2023. PMID: 37375673 Free PMC article.

- Textural characteristics and color analyses of 3D printed gluten-free pizza dough and crust. Dey S, Maurya C, Hettiarachchy N, Seo HS, Zhou W. Dey S, et al. J Food Sci Technol. 2023 Feb;60(2):453-463. doi: 10.1007/s13197-022-05596-w. Epub 2022 Dec 22. J Food Sci Technol. 2023. PMID: 36712201 Free PMC article.

- Technological interventions in improving the functionality of proteins during processing of meat analogs. Kumar P, Sharma N, Ahmed MA, Verma AK, Umaraw P, Mehta N, Abubakar AA, Hayat MN, Kaka U, Lee SJ, Sazili AQ. Kumar P, et al. Front Nutr. 2022 Dec 19;9:1044024. doi: 10.3389/fnut.2022.1044024. eCollection 2022. Front Nutr. 2022. PMID: 36601080 Free PMC article. Review.

- Arzani, A. in Flour and breads and their fortification in health and disease prevention 1st edn, (eds. Preedy, V. R., Watson, R. R. & Patel, V. B.) Ch. 7 (Elsevier, Amsterdam, 2011).

- Chazan M, Lehner M. An ancient analogy: pot baked bread in ancient Egypt and Mesopotamia. Paléorient. 1990;16:21–35. doi: 10.3406/paleo.1990.4530. - DOI

- Hansson, A. M. Grain-paste, porridge and bread—ancient cereal-based food. Labor. Arkeol.7, 5–20 (1994).

- Legras JL, Merdinoglu D, Cornuet JM, Karst F. Bread, beer and wine: Saccharomyces cerevisiae diversity reflects human history. Mol. Ecol. 2007;16:2091–2102. doi: 10.1111/j.1365-294X.2007.03266.x. - DOI - PubMed

- Miller, N. & Wetterstrom, W. in The Cambridge World History of Food 1st edn, Vol. 2 (eds. Kiple, K. & Ornelas, K.). Ch. VA (Cambridge Univ. Press, Cambridge, 2000).

Publication types

- Search in MeSH

Related information

Linkout - more resources, full text sources.

- Europe PubMed Central

- Nature Publishing Group

- PubMed Central

Research Materials

- NCI CPTC Antibody Characterization Program

- Citation Manager

NCBI Literature Resources

MeSH PMC Bookshelf Disclaimer

The PubMed wordmark and PubMed logo are registered trademarks of the U.S. Department of Health and Human Services (HHS). Unauthorized use of these marks is strictly prohibited.

Thank you for visiting nature.com. You are using a browser version with limited support for CSS. To obtain the best experience, we recommend you use a more up to date browser (or turn off compatibility mode in Internet Explorer). In the meantime, to ensure continued support, we are displaying the site without styles and JavaScript.

- View all journals

- Explore content

- About the journal

- Publish with us

- Sign up for alerts

- Review Article

- Open access

- Published: 01 May 2019

Recent practical researches in the development of gluten-free breads

- Hiroyuki Yano ORCID: orcid.org/0000-0002-0910-854X 1

npj Science of Food volume 3 , Article number: 7 ( 2019 ) Cite this article

26k Accesses

41 Citations

5 Altmetric

Metrics details

Wheat bread is consumed globally and has played a critical role in the story of civilization since the development of agriculture. While the aroma and flavor of this staple food continue to delight and satisfy most people, some individuals have a specific allergy to wheat or a genetic disposition to celiac disease. To improve the quality of life of these patients from a dietary standpoint, food-processing researchers have been seeking to develop high-quality gluten-free bread. As the quality of wheat breads depends largely on the viscoelastic properties of gluten, various ingredients have been employed to simulate its effects, such as hydrocolloids, transglutaminase, and proteases. Recent attempts have included the use of redox regulation as well as particle-stabilized foam. In this short review, we introduce the ongoing advancements in the development of gluten-free bread, by our laboratory as well as others, focusing mainly on rice-based breads. The social and scientific contexts of these efforts are also mentioned.

Similar content being viewed by others

Sustainable plant-based ingredients as wheat flour substitutes in bread making

Strategies to improve wheat for human health

Physico-chemical properties of an innovative gluten-free, low-carbohydrate and high protein-bread enriched with pea protein powder

Introduction.

The aroma emanating from a bread bakery is unmistakably alluring. The flavor and crunchy texture of wheat breads sharpen our appetite and satisfy our basic human cravings for comfort as well as nutrition. Indeed, human beings are so enchanted by bread that it is much more than a “staple food”; it has been called “the staff of life”. Breadmaking has a long and fascinating story. 1 , 2 , 3 , 4 It is generally accepted that breadmaking dates back to the New Stone Age, from 8000 to 10,000 BC, and originated around the Fertile Crescent and consisted of emmer and einkorn wheat grains. 1 At first the grains were consumed as porridge. Then, grains that had been hand-crushed using knocking stones were mixed with water and baked on a heated stone with a cover of hot ash, resulting in an unfermented, flat bread. Later, around 6000 BC, people in southern Mesopotamia started using sourdough, 5 speculated to have been developed accidently in an abandoned mixture of flour and water. This first leavened bread dough, which contained fermentation gas, swelled up in the baking process. In ~3000 BC, the Egyptians improved bread by adding yeast, developing what would become the prototype of modern bread. They dehulled and milled wheat grains using saddle querns, the most ancient type of quern stones, 6 which were later replaced by rotary querns and are used even today. Breadmaking and beer production in Egypt are closely related and are considered evidence of a high degree of civilization. 7 Bread was made not only with flour prepared from raw grains, but sometimes also with malt (germinated grains). Moreover, water with a blend of cooked and uncooked malt was used in brewing. The mixture was strained free of husk before inoculation with yeast.

The precise origin of bread has still not been determined. Recent reports show archaeobotanical evidence that the origins of bread date back to 14,400 years ago. 8 Progress in archaeology will eventually clarify the origin of bread, along with some sense of how bread fits into the larger culture of ancient civilizations. Wheat bread is now one of the most representative food in the world. A unique property of wheat gluten realizes bread with high quality. However, some genetically predisposed people cannot eat wheat bread, because gluten causes harmful reactions to them. In this short review, we will summarize the gluten-dependent swelling mechanism of wheat bread and the recent scientific effort to make bread without gluten.

Modern wheat breadmaking

Simply stated, breadmaking is composed of three steps: mixing/sheeting, fermenting, and baking processes. 9 In the mixing process, wheat flour, water, yeast, sugar, salt, oil, and other components are mixed and kneaded. Here, the ingredients are blended homogeneously and hydrated, resulting in the development of the all-important gluten network. 10 Gluten is made from two major wheat proteins together comprising 85% of wheat endosperm protein: gliadin and glutenin. Kneading of wheat dough promotes the hydrogen bonding and disulfide cross-linking interactions of these proteins, eventually producing a viscoelastic and highly conformational protein network termed “gluten”. 11 Yeast grows fast in the dough, feeding on supplemental sugar, until it consumes all available oxygen. Then, it shifts metabolism from aerobic respiration to anaerobic fermentation. In the subsequent fermentation process, yeast generates fermentation gas, mainly composed of carbon dioxide and other components, such as ethanol:

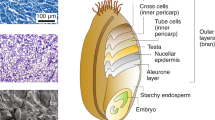

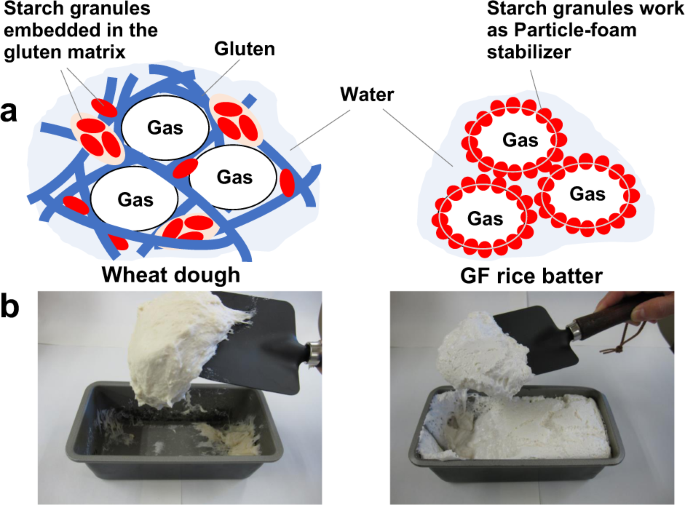

In wheat dough, the gas is confined in the continuous “gluten matrix”, 12 which is composed of the viscoelastic gluten network and other components, such as starch granules and water (Fig. 1a ). Thus, in the beginning of the fermentation process, many small gas cells are produced throughout the dough, like so many small balloons. As the fermentation proceeds, each small gas cell grows bigger, and the dough rises. In the following baking process, the gas cell inflates further by heat, resulting in the expansion, namely, “oven spring” of the dough. 13 The starch molecules are gelatinized by heat, so that the gluten matrix forming the envelopes of the “balloons” become hardened, thus constructing the stable crumb framework. 14 Concurrently, the crust, or surface of the bread dough, is hardened as well as browned by the Maillard reaction between the sugars and amino acids. 15 Finally, the breadmaking is completed, emitting a fresh aroma. 16

Comparison of the swelling mechanism ( a ) and appearance ( b ) of fermenting wheat dough and additive-free, gluten-free (GF) rice batter

The preparation of ingredients, especially flour, is also a critical step. Wheat grain is composed mainly of three parts: the endosperm, germ, and bran. 17 In the endosperm, which is the major constituent of the polished grain, starch granules are embedded in a protein matrix. 18 Wheat flour is produced by grinding whole-wheat grains or polished ones mechanically. 19 Impact mills, such as hammer mills and pin mills, accomplish particle size reduction by exposing seeds to a set of rotating hammer or pins that fracture the seeds, while roller and stone mills compress the seeds between two hardened surfaces. 20 During the milling of wheat grains, a portion of the starch granules are mechanically damaged. 21 The extent of the damage depends on wheat variety (hard or soft type) as well as milling conditions. In the mixing and fermentation steps of breadmaking, damaged starch accelerates the absorption of water to the starch granules, resulting in the activation of local amylases, leading to the degradation of starch molecules into dextrin and maltose. 22 Consequently, yeast activity and the final bread volume is increased. However, excessive starch damage produces wet or sticky dough and bread with poor quality. Thus, control of flour quality in terms of the starch damage is critical in the milling industry. 23

In other words, intact and damaged starch granules each have their respective role in the making of wheat bread—and, as we will show, in rice-flour breads as well. In the case of wheat dough, intact starch granules constitute the gluten matrix, while damaged ones activate fermentation. Generally, the extent of starch damage in commercially available wheat flours is 10–15%. 19

Social demand for gluten-free food

Gluten intolerance.

While the unique viscoelastic property of gluten realizes wheat bread with high quality, some people choose to or must follow a gluten-free diet. Recent reviews well summarize the background and status quo of gluten-free diets, 24 , 25 so only the outline will be mentioned here. Gluten intolerance includes autoimmune celiac disease (CD), wheat allergy, and non-celiac gluten sensitivity (NCGS). Celiac disease is an autoimmune disorder caused by genetic as well as environmental factors. 26 In CD patients, ingestion of gluten leads to small intestinal damage, typically leading to malabsorption. Its prevalence in the United States and Europe is estimated to reach about 1%. Gluten protein has protease-resistant regions in its structure. 27 Digestion of gluten in the human gastrointestinal tract generates “pathogenic” peptides that occasionally reach the lamina propria, where the peptides are deamidated by local transglutaminase. 28 The modified gluten peptides have a higher affinity to human leukocyte antigen (HLA)–DQ2 as well as HLA–DQ8 molecules, 29 which are present only in the small percentage of people carrying the HLA–DQ2 or the DQ8 haplotype. 30 This bonding results in the presentation of the gluten peptides to T cells, thereby triggering further malignant immune response in those with CD. In addition, tissue transglutaminase cross-links covalently to gliadin molecules. The protein complexes with new epitopes are considered to trigger the primary immune response as well. Antibodies against tissue transglutaminase are characteristic of CD. 31

In contrast, food allergy to wheat is characterized by T helper type 2 (Th2) activation, which can result in immunoglobulin E (IgE) and non-IgE-mediated reactions. 32 The IgE-mediated wheat allergy reactions usually occur immediately after contact of wheat, and are characterized by the occurrence of wheat-specific IgE antibodies in serum. Ingestion of wheat causes food allergy, while inhalation of wheat causes respiratory allergy to genetically predisposed individuals. A food allergy to wheat may cause a life-threatening reaction, such as anaphylaxis and wheat-dependent, exercise-induced anaphylaxis. 33 In contrast, repetitive exposure to wheat flour may cause baker’s asthma or rhinitis, mostly characterized as occupational allergic diseases. 34 Non-IgE- mediated food allergy reactions to wheat usually occur hours or even days after ingestion of wheat products and are characterized by chronic eosinophilic inflammation of the gastrointestinal tract. 35 There is a variability among reports of wheat allergy prevalence due to the differences in the diagnostic criteria, methodology, age, and geography. 36 The prevalence of wheat allergy is estimated to be 0.9% in the United Kingdom (based on questionnaire response), 37 3.6% in the United States (based on measurement of anti-wheat-specific IgE antibodies), 38 and 0.2% in Japan (based on a combination of questionnaire-based examination, skin prick test, and serum omega-5 gliadin-specific IgE test). 39

Non-celiac gluten sensitivity (NCGS) is a recently proposed, increasingly recognized clinical condition in patients in whom celiac disease and wheat allergy have been ruled out. It is characterized by intestinal and extra-intestinal symptoms triggered by the ingestion of gluten-containing foods. 40 Due to the lack of a reliable biomarker, confirmation of an NCGS diagnosis relies only on a double-blind placebo-controlled (DBPC) gluten challenge. 41

So far, a gluten-free diet is the only safe and effective treatment for the above conditions of gluten intolerance. 32

Gluten-free “lifestylers”

Demand for gluten-free foods is not limited to the gluten-intolerant population. Although it is not clear whether a gluten-free diet is beneficial for one’s health, some gluten-tolerant consumers believe that gluten-free food products are simply healthier. 42 , 43 This can be partly explained by a kind of “health halo” effect, making consumers believe that products with “free-from” label are healthier overall. 44 Besides, some popular books by bestseller authors, athletes, and celebrities have encouraged a gluten-free diet. An online questionnaire survey demonstrated that 41% of non-celiac athletes, including Olympic medalists, follow a gluten-free diet 50–100% of the time, and that adoption of the diet in most cases was not based on a medical rationale and may have been driven by the perception that gluten removal provides health benefits and an ergogenic edge. 45 Approximately 13% of young adults are reported to value gluten-free food; this population is more likely to engage in other healthy dietary behaviors, such as eating breakfast daily and eating more fruits/vegetables while simultaneously pursuing questionable behaviors, such as using diet pills to control weight. 42

A double-blind randomized study found that the supposed health benefit of a gluten-free diet has no evidence base in individuals who do not have celiac disease or irritable bowel syndrome, demonstrating that gluten is unlikely to be the culprit for gastrointestinal symptoms or fatigue in otherwise healthy individuals. 43 Moreover, commercially available gluten-free food products tend to contain ingredients with less diversity and less nutritional quality compared with their gluten-containing counterparts. 46 , 47 Other studies claim that despite recent improvements in the formulation and availability of gluten-free foods, they still are less available and more expensive than gluten-containing versions. 48 They generally have adequate levels of fiber and sugar, but lower levels of protein and higher levels of fat compared with their gluten-containing counterparts. 48 Also, very few gluten-free foods are fortified with micronutrients. 48

The gluten-free products market was valued at USD 4.18 billion in 2017 and this is projected to reach USD 6.47 billion by 2023, at a compound average growth rate of 7.6% during the forecast period. 49 The gluten-free diet has become the mainstream rather than just supporting a niche market.

Developments of gluten-free breads

As mentioned in the previous sections, demand for the development of gluten-free foods is growing. 50 Much of the focus is on bread products, as bread is an important staple food. Rice is considered a suitable substitute for wheat, as it is available worldwide and is less allergenic. So, development of rice-based gluten-free breads is the main topic of this review. It is not easy to make bread without using wheat flour or gluten, as bread’s quality depends on the properties and functionality of gluten. 25 In a wheat flour dough, the gluten matrix, composed mainly of the protein network of gluten, starch granules, and water (Fig. 1a ), encloses the fermentation gas, making small “balloons”. Thus, the dough rises as the fermentation proceeds. On the other hand, hydration of flour from gluten-free cereals, such as rice, results in a runny “batter” rather than viscoelastic “dough” as their proteins do not possess the network-forming properties typically found in gluten. 51 Therefore, the fermentation gases rise to the surface while starch granules and yeast settle. 52 Generally, a gluten-free batter without a thickening agent, such as hydrocolloids, becomes foamy. 53 , 54

Several efforts have been made in the development of gluten-free breads. Typical gluten-free breads contain hydrocolloids (e.g., xanthan gum, guar gum, etc.) which increase the viscosity of the liquid phase, keeping the starch granules, yeast, and gas bubbles suspended in the fermentation process. 52 , 55 The subsequent baking process gelatinizes the starch and hardens around the hydrocolloid membrane surrounding the air bubbles to set the crumb structure. As a surface-active hydrocolloid, hydroxypropyl methylcellulose (HPMC) behaves somewhat differently. It has hydrophobic methyl ester/hydroxypropyl groups in addition to hydrophilic cellulose regions. Thus, HPMC stays at the gas/liquid interface, uniquely stabilizing the bubbles and preventing coalescence. 52 , 56 Moreover, as HPMC is thermoreversible, 57 it also helps harden the bubble membrane in the baking process. 58

Another recent approach includes enzymatic treatment of gluten-free batter. 51 Transglutaminase (EC 2.3.2.13) catalyzes the acyl-transfer reaction between primary amino groups on protein-bound lysine residues and γ-carboxyamide groups on protein-bound glutamine residues. 59 Thus, transglutaminase is capable of introducing covalent cross-links between proteins. 60 The protein cross-linking ability has been shown to transform weak gluten into a strong gluten, with measurable effects on rheological behavior. 61 The addition of transglutaminase, along with HPMC, to a gluten-free rice batter resulted in its improved elastic and viscous behavior, as well as a higher specific volume and softer crumbs in the resulting bread. 62 The improvement in the viscoelastic properties of the rice batter appeared to be associated with the enhanced capability of the rice flour to retain the carbon dioxide produced during proofing. The quantitative decrease of free amino groups of proteins suggested that this improvement was due to the cross-linking of protein, that is, the generation of a gluten substitute, supplementing the role of HPMC in the baking of rice bread. 62 Microstructure analyses of a rice-based bread fortified with skim milk or egg powder using confocal laser-scanning microscopy (CLSM) verified that addition of transglutaminase promoted the formation of a protein network in the gluten-free bread that mimicked the gluten network in wheat breads. 63 The networking efficiency of transglutaminase depends on both the correct protein substrates and the level of enzyme addition. Thus, formation of the appropriate protein network under the right conditions should improve the overall quality of gluten-free bread by enhancing loaf volume and crumb characteristics, as well as appearance.

Improvement of the gas-retaining capability of gluten-free batter using protease, a seemingly paradoxical strategy for cross-linking, is also in progress. Protease has actually been used to weaken wheat dough by cleaving a portion of the gluten network. 64 However, treatment of a brown rice batter with bacterial protease improved bread quality by significantly increasing the specific volume while decreasing crumb hardness and chewiness. 65 CLSM images of the bread crumbs suggested that the gelatinized starch phase was the main structure component in the protease-treated bread. Thus, protease may partially degrade the large macromolecular protein complex embedding starch granules, 66 , 67 resulting in improved continuity of the starch phase as well as better rheological properties of the batter. Treatment of rice batter with a protease from Aspergillus oryzae increased its viscosity and resulted in bread with a high specific volume. Optical microscopic observation of the batter suggested that partially degraded protein, possibly glutelin, and starch granules formed aggregations containing voids. 54 This fine network of interlinked protein‒starch aggregates resulted in gas cell stabilization. 54 Proteases are mainly categorized into four classes based on the catalytic mechanism: metallo, serine, cysteine, and aspartyl proteases. 68 Comparative analyses of the proteases 69 , 70 demonstrated that metallo, serine, and cysteine proteases, but not aspartyl protease, are effective additives for improving the quality of gluten-free rice breads.

Application of the redox regulation

Addition of glutathione, a ubiquitous natural peptide, facilitated the deformation of rice batter, thus increasing its elasticity in the early stages of bread baking and increasing the volume of the resulting bread. 53 , 71 Below, we would like to introduce briefly how glutathione can be used in making gluten-free rice bread. The disulfide bond is a cross-link between two cysteine residues and plays an important role in the structure/function of proteins. 72 Redox regulation, control of reduction/oxidation of the disulfide bonds, as well as phosphorylation are the two major post-translational modifications of proteins. 73 Thioredoxin (Trx), 74 a small 12 -kDa protein, and glutathione, 75 a natural tripeptide, play central roles in the redox-dependent regulatory mechanisms.

Trx reduces the disulfide bond of its target protein specifically. In the reactions below, oxidative status is abbreviated as “OX” and reduced status is abbreviated as “RED”:

Glutathione (GSH) is a tripeptide with a free SH group. Two molecules of glutathione occasionally cross-link with an intermolecular disulfide bond to make “oxidized” glutathione (GSSG). Glutathione’s reaction occasionally entails glutathionylation (GL): 76

Redox regulation has been a key target of Dr. Bob Buchanan’s laboratory, University of California, Berkeley, after he clarified the Trx-dependent regulatory mechanism in photosynthesis. 77 , 78 In the proteomic analyses of plant biochemistry mostly performed by the Berkeley group, 79 , 80 , 81 , 82 we have found that redox regulation occurs in many aspects of plant life and plays critical roles in plant biology: seed germination/maturation, photosynthesis, defense against oxidative stress/pathogens, and others. 83 Then, thinking in the opposite direction, modification of the disulfide bonds in biology, that is, artificial activation of the redox regulatory mechanism, might lead to the production of a new, useful plant. Following this hypothesis, overexpression of Trx in plants was first tried in the starchy endosperm of barley. 84 The transformant germinated earlier than the wild type. Also, enzymes in charge of starch mobilization appeared earlier. As fast germination of barley seeds reduces the production cost and improves the quality of beer, 85 the results suggest the practical utility of Trx transformants. Conversely, underexpression of Trx in white wheat seed has been tried. White wheat has received increasing attention, as it is naturally white and needs no bleaching for uses, such as breadmaking. However, white wheat grains tend to germinate on the spike before harvest. 86 The preharvest sprouting (PHS) reduces the crop yield as well as the quality of the seeds and the flour. Rainfall or high humidity in the grain-filling season leads to PHS, and causes farmers significant financial losses. 87 Suppression of Trx in the starchy endosperm led to improved PHS resistance in the transformants 88 without affecting the crop yield or flour quality. 89

These two findings reported by the Berkeley group are the first discovery that control of Trx expression, that is, artificial redox regulation, affects the physiological processes of plants. Although risk assessment of genetically modified organisms (GMOs) is a critical issue, 90 the characteristics of these and other trial model plants provide the possibility of the industrial application of redox regulation. 91

More recently, we have sought to use this strategy to enable rice batter to confine fermentation gas. Glutathione was added to rice batter in an attempt to transform the intramolecular disulfide bonds of rice proteins into intermolecular disulfide bonds and eventually form a gluten-like network. Both reduced glutathione (GSH) and oxidized glutathione (GSSG) were found to be successful in swelling gluten-free rice batter and bread. 53 , 71 However, contrary to our expectations, analysis of the proteins revealed that no gluten-like protein network was formed. In contrast, microstructure and biochemical analyses suggested that glutathione cleaved the disulfide-linked glutelin polymers embedding the starch granules. The glutelin polymer has been suggested to work as a hindrance to the absorption of water by starch molecules when water is added to a rice flour; 66 glutathione may fray this barrier to make the batter more consistent and viscous, thereby improving its gas-holding capability in the fermentation process, 53 as is the case with protease-treated rice batter. 65 Although the number of its applications in food processing has been limited so far, 91 glutathione appears to be a promising tool for developing food with new properties. Glutathione is usable as a food ingredient in the United States 92 and some east Asian countries. For example, glutathione-based oral dietary supplements have been accorded the status of a Generally Recognized as Safe (GRAS) constituent with Section 201(s) of the Federal Food, Drug, and Cosmetic Act of the US Food and Drug Administration (US-FDA). 93

On the other hand, usage of glutathione for food has some limitations. First, glutathione is not usable as a food in all countries. In Japan, for instance, it is recognized as medicine, and cannot be incorporated as a food additive. 94 Second, GSH-added rice batter has been shown to yield a slight amount of hydrogen sulfide (0.43 ppm) and methyl mercaptan (0.106 ppm) in the headspace gas of the bread. 71 Generation of hydrogen sulfide in heated meat or purified GSH is well known; 95 indeed, a slight amount of hydrogen sulfide contributes to the pleasant aroma of cooked meat 96 and rice. 97 Usage of GSSG in breadmaking instead of GSH significantly reduced the generation of these sulfur compounds, 71 and sensory evaluation demonstrated that the aroma of GSSG-added rice bread was almost equivalent to that of non-added bread. 98 However, we sought to develop rice bread without glutathione or any other additives.

In the process of developing glutathione-added rice bread, we found that the control sample, that is, “non-added bread”, occasionally swelled in fermentation. Although it collapsed mostly in the following baking process, we expected that if optimal conditions could be found, we could make an additive-free, gluten-free rice bread from solely the basic ingredients: rice flour, water, yeast, sugar, salt, and oil.

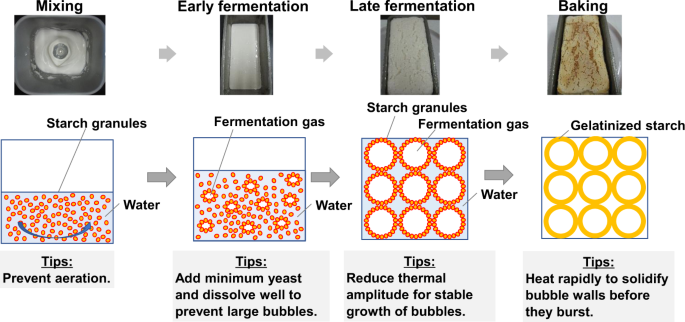

Additive-free, gluten-free rice bread

The development of additive-free, gluten-free rice bread has taken a trial-and-error rather than a strategic approach. 99 , 100 First, we tried several commercially available rice flours and found that flours with low-starch damage (<5%) were the most suitable. The physical property of the gluten-free rice batter appeared quite different from the familiar viscoelastic wheat dough. It had an appearance and texture of a slurry with low viscosity. So, lots of “cooking tips” have been discerned for the breadmaking process. For example, as rice batter tends to make lumps, we paid attention in the mixing procedure to avoid lumps. Also, the dried yeast needs to be dissolved completely. Generation of bubbles of different sizes due to heterogeneous distribution of dried yeast may result in their coalescence 101 and a sudden shrinkage of the batter in the fermentation process. The breadmaking processes, i.e., mixing of the batter, fermentation and baking, as well as tips for successful making in the respective processes, are mentioned in a later section.

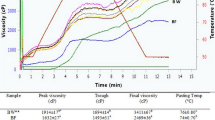

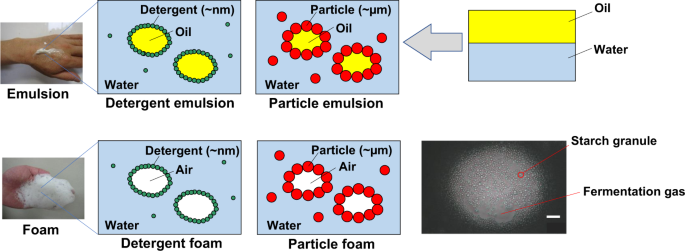

To clarify how the gluten-free batter swells without additives, we sought to investigate the microstructure of the fermenting batter. The fermenting batter appeared like a meringue and was quite different from wheat dough, which is so viscoelastic that its full mass can be lifted with a scoop (Fig. 1b ). As it was not easy to freeze the fragile batter without destroying the delicate structure, a sectioned specimen for microscope observation could not be made. Instead, freshly made batter was sandwiched between a microscope slide and a coverslip and the batter was left at room temperature to ferment there. Optical microscopic observation revealed the microstructure: bubbles covered by starch granules (Fig. 2 ). The structure was entirely different from that of the typical wheat dough, in which gas cells are surrounded by the gluten matrix made by a network of gluten protein and starch granules. 102 In contrast, it had a similar structure to a “particle emulsion” 101 in which rice granules stabilize the interface between oil and water (Fig. 2 ). 103 Thus, it was suggested that the bubble observed in an additive-free, gluten-free rice batter had the structure of a “particle foam” (Figs. 1a , 2 ). 101

Explanatory figure of particle emulsion/foam. Adapted from refs. 99 , 100 . Scale bar: 30 µm. Copyright (2017), with permission from Elsevier

The hypothetical mechanism is illustrated in Fig. 2 . Generally, oil and water do not mix. However, when they are mixed well in the presence of a detergent, microscopic oil droplets covered by detergent molecules disperse throughout water. This is a classic emulsion. Likewise, aeration of water in the presence of detergent results in a foam. A small amount of air is surrounded by a thin film of water, in which detergent molecules stabilize the boundary.

At the beginning of the 20th century, solid particles were found able to adsorb onto the interface between oil and water, and play a similar role to that of detergent molecules. 104 , 105 This is called a “particle-stabilized emulsion” or “particle emulsion”. Starch granules of native rice, maize, wheat, 103 quinoa, 106 high-pressure treated corn starch granules, 107 chemically modified waxy maize and tapioca, 108 as well as rice starch granules 109 have been reported to form particle emulsions. A particle-stabilized foam occurs in the same manner. Particle emulsions/foams have received renewed attention during the past decade, as recent advancement in nanoparticle technology accelerates research trends. 110 , 111 Moreover, such foams have potential applications in a wide variety of industries, including foods, pharmaceuticals, and cosmetics. One of the key advantages of the mechanism for foodstuff applications is that microparticles of biological origin, such as starch granules, cellulose, or protein particles, work as stabilizers. 101 Our report showed for the first time that rice starch granules stabilize particle “foam” in an additive-free, gluten-free rice batter. 99

The breadmaking processes and tips for the successful gluten-free breadmaking from rice flour are summarized in Fig. 3 . In the early stage of fermentation, yeast produces fermentation gas, composed mainly of carbon dioxide and alcohol. Ordinarily, the batter cannot hold the gas and becomes foamy. 53 , 54 However, if rice flour with low-starch damage is used and breadmaking is performed with the right conditions, the fermentation gas is trapped in the batter. 99 Thus, small bubbles appear throughout the batter. The small bubbles are particle foams in which fermentation gas is surrounded by starch granules. As the fermentation proceeds, the fragile bubbles gradually grow bigger, making the whole batter rise. Here, it is critical to keep the temperature stable, as fragile bubbles tend to burst in fluctuating temperatures. In the late stage of fermentation, the swollen bubbles should be heated rapidly to make the starch granules gelatinize, that is, to solidify the bubble walls. The most swollen bubbles are the most fragile, so rapid heating is the key.

Summary of the procedures for making additive-free rice bread and “cooking tips” for each step. Adapted from ref., 100 with permission

The overall process resembles the synthesis of a polyacrylamide hydrogel, in which modified nanoparticles stabilize an air/water (acrylamide solution) emulsion, and the macroporous structure is fixed by thermal-induced polymerization. 112

We have investigated several commercially available rice flours and found that rice flours with less starch damage (<5%) make bread with a higher specific volume. 99 Higher starch damage tends to facilitate greater absorption of water by starch granules. 113 The hydrophobicity/hydrophilicity ratio determines the aptitude of starch granules to form particle foam. 114 Thus, to prevent destabilization of the fragile bubbles in the fermentation process, it is important to maintain the proper hydrophobicity/ hydrophilicity ratio. Our success in making bread using flour with less starch damage, that is, less water absorption, seems consistent with the hypothetical mechanism. In this context, reduction of surface tension by hydrophobic treatment of rice starch granules was successful in making a stable particle emulsion. 108 , 109

From another point of view, if rice starch granules are capable of constituting a particle foam, they should have the ability to mimic the function of detergents, that is, to reduce the surface tension of water. Starch granules with less starch damage (4.7 w/w%) effectively reduced the surface tension of water from 73 to 35 mN/m. In contrast, starch granules with higher starch damage (9.8 w/w%) were not as effective, reducing the surface tension to only 47 mN/m. 99

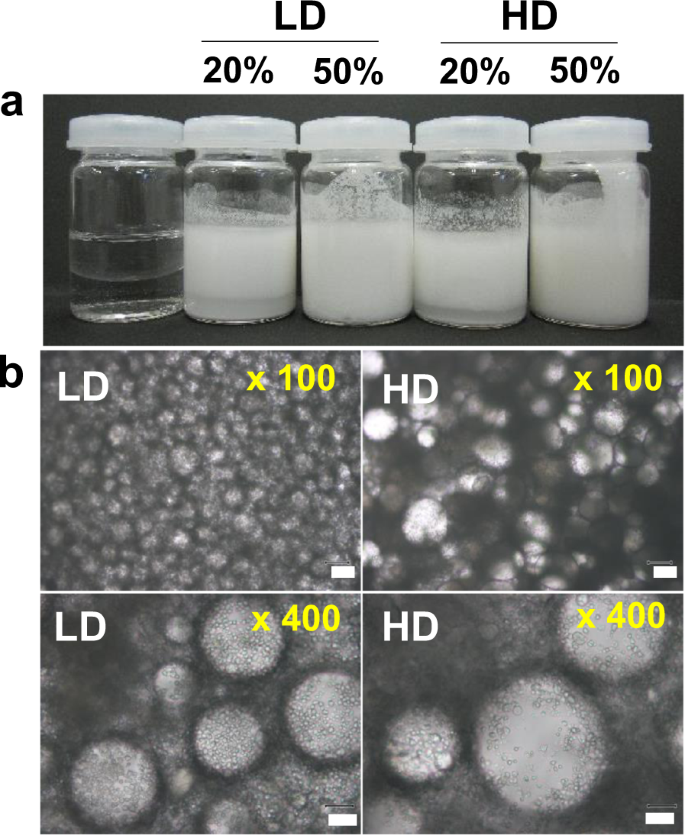

Starch granules show emulsion-forming ability by stabilizing the water/tetradecane interface. 108 So, similar experiments were conducted using starch granules with low- and high-starch damage (Fig. 4 ). Both starch granules made stable water/tetradecane emulsions (Fig. 4a ). However, the microstructures of the emulsions were somewhat different (Fig. 4b ). Optical microscopic analyses of the emulsions showed that starch granules with less starch damage (LD) covered the oil droplets densely. In contrast, in the case of rice granules with higher starch damage (HD), swollen granules were occasionally seen, and the oil droplets were not covered completely. Thus, rice granules with low-starch damage demonstrated better particle-emulsion-forming ability compared with the high-starch-damage counterparts. This was consistent with the observation that rice starch granules with low-starch damage were suitable for constructing particle foam, that is, to make additive-free rice bread.

a Water/tetradecane emulsions formed by starch granules at different rice flour concentrations. From left to right: control (no flour), addition of rice flour with low-starch damage (20% w/w, 50% w/w), as well as high-starch damage (20% w/w, 50% w/w). b Optical microscopic analyses of the emulsion. Rice flour with low- (LD) and high- (HD) starch damage was compared. Adapted from ref. 99 Scale bar: 100 µm for ×100, and 30 µm for ×400, respectively. Copyright (2017), with permission from Elsevier

All these three observations support the hypothetical particle foam theory. Verification studies are in progress in our lab.

Several approaches in the development of gluten-free bread by our own laboratory and others have been introduced in this review, together with the social and scientific context of these efforts. The research is aimed to improve the quality of life of celiac disease or wheat allergy patients. Better bread quality (flavor, texture, and volume), reduced production cost, and wider availability are all important issues. 115 For example, so far, rice bread lacks the mouth-watering aroma of freshly baked wheat bread. It is not clear whether this is inevitable or whether a better selection of ingredients or an improved breadmaking procedure could lead to improvement of the aroma and flavor of rice bread, such that it becomes comparable with that of wheat bread. Besides, rice breads tend to be sticky compared with wheat bread. Also, gelatinized rice starch tends to retrograde faster, 116 so the bread is prone to become stale and hardened faster, 117 resulting in a shorter shelf life. 118 Using rice varieties with intermediate amylose content and a low water absorption index may give superior crumb properties. 119

Recent wide availability of household breadmaking countertop appliances has prompted our laboratory and others to develop gluten-free bread recipes suitable for these machines. Providing specific ingredients, such as fitted rice flour sold along with the breadmaker, may help consumers experience success in making custom gluten-free bread at home. Improving the machines by incorporating an induction-heating (IH) system may be suitable for making “particle-foam” type rice bread, as an IH system guarantees stable temperature control in fermentation as well as rapid heating in the baking process. 120 Addition of micronutrients and functional food ingredients is also an important theme. Further studies may thus improve the bread quality to be comparable to that of wheat bread and to improve the quality of wheat-sensitive patients’ life through providing a satisfactory diet.

Arzani, A. in Flour and breads and their fortification in health and disease prevention 1st edn, (eds. Preedy, V. R., Watson, R. R. & Patel, V. B.) Ch. 7 (Elsevier, Amsterdam, 2011).

Chazan, M. & Lehner, M. An ancient analogy: pot baked bread in ancient Egypt and Mesopotamia. Paléorient 16 , 21–35 (1990).

Article Google Scholar

Hansson, A. M. Grain-paste, porridge and bread—ancient cereal-based food. Labor. Arkeol. 7 , 5–20 (1994).

Legras, J. L., Merdinoglu, D., Cornuet, J. M. & Karst, F. Bread, beer and wine: Saccharomyces cerevisiae diversity reflects human history. Mol. Ecol. 16 , 2091–2102 (2007).

Article CAS PubMed Google Scholar

Miller, N. & Wetterstrom, W. in The Cambridge World History of Food 1st edn, Vol. 2 (eds. Kiple, K. & Ornelas, K.). Ch. VA (Cambridge Univ. Press, Cambridge, 2000).

Samuel, D. Bread making and social interactions at the Amarna workmen’s village, Egypt. World Archaeol. 31 , 121–144 (1999).

Samuel, D. Investigation of ancient Egyptian baking and brewing methods by correlative microscopy. Science 273 , 488–490 (1996).

Arranz-Otaegui, A., Carretero, L. G., Ramsey, M. N., Fuller, D. Q. & Richter, T. Archaeobotanical evidence reveals the origins of bread 14,400 years ago in northeastern Jordan. Proc. Natl Acad. Sci. USA 115 , 7925–7930 (2018).

Article CAS PubMed PubMed Central Google Scholar

Dobraszczyk, B. J. & Morgenstern, M. P. Review: rheology and the breadmaking process. J. Cereal Sci. 38 , 229–245 (2003).

Biesiekierski, J. R. What is gluten? J. Gastroenterol. Hepatol. 32 , 78–81 (2017).

Wieser, H. Chemistry of gluten proteins. Food Microbiol. 24 , 115–119 (2007).

Gan, Z. et al. The microstructure and gas retention of bread dough. J. Cereal Sci. 12 , 15–24 (1990).

Wang, F. C. & Sun, X. S. Thermal expansion of flour-water dough measured with a dynamic mechanical analyzer. Cereal Chem. 76 , 87–91 (1999).

Article CAS Google Scholar

Kusunose, C., Fujii, T. & Matsumoto, H. Role of starch granules in controlling expansion of dough during baking. Cereal Chem. 76 , 920–924 (1999).

Helou, C., Jacolot, P., Niquet-Léridon, C., Gadonna-Widehem, P. & Tessier, F. J. Maillard reaction products in bread: a novel semi-quantitative method for evaluating melanoidins in bread. Food Chem. 190 , 904–911 (2016).

Pico, J., Bernal, J. & Gómez, M. Wheat bread aroma compounds in crumb and crust: a review. Food Res. Int. 75 , 200–215 (2015).

Brouns, F., Hemery, Y., Price, R. & Anson, N. Wheat aleurone: separation, composition, health aspects, and potential food use. Crit. Rev. Food Sci. Nutr. 52 , 553–568 (2012).

Rojas, J. A., Rosell, C. M., Benedito de Barber, C., Pérez-Munuera, I. & Lluch, M. A.The baking process of wheat rolls followed by cryo scanning electron microscopy. Eur. Food Res. Technol. 212 , 57–63 (2000).

Prabhasankar, P. & Rao, P. H. Effect of different milling methods on chemical composition of whole wheat flour. Eur. Food Res. Technol. 213 , 465–469 (2001).

Maskus, H., Bourré, L., Fraser, S., Sarkar, A. & Malcolmson, L. Effects of grinding method on the compositional, physical, and functional properties of whole and split yellow pea flours. Cereal Foods World 61 , 59–64 (2016).

Ferrand, E. A. Flour properties in relation to the modern bread processes in the United Kingdom with special reference to alpha-amylase and starch damage. Cereal Chem. 41 , 98–111 (1964).

Google Scholar

Goesaert, H. et al. Wheat flour constituents: how they impact bread quality, and how to impact their functionality. Trends Food Sci. Technol. 16 , 12–30 (2005).

Miralbés, C. Quality control in the milling industry using near infrared transmittance spectroscopy. Food Chem. 88 , 621–628 (2004).